As a ABYC electrical tech I have tested installed and designed countless battery systems. One of the biggest complaints I get from my customers is my batteries don’t last when I am at anchor. In most cases I have found the boat owner just doesn’t really understand how batteries really work.

To start lets go back to electricity basics. Think of Voltage as pressure pushing electricity in and out of our battery system. Second is current flow or Amps, the speed at witch the battery is being depleted. The amp hour rating is the maximum Amp capacity a battery is capable of delivering at given rate of discharge.

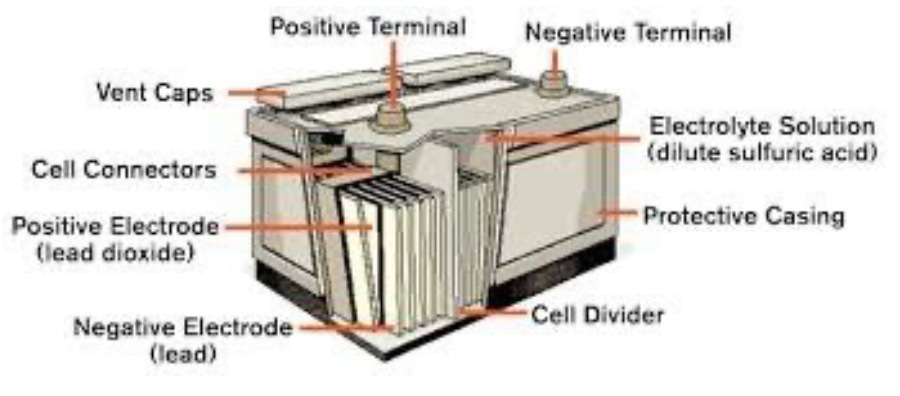

The combination of cells and plates in a typical wet cell battery; The positive plate is made of an alloy of lead and antimony with lead dioxide pressed onto the surface. In an AGM batteries they may use lead and calcium as the alloy for the grid. The alloy makes the grid plates stronger. The negative plate is made of pure lead. A chemical reaction is made with the electrolyte. The electrolyte being sulfuric acid and water. AGM batteries use the exact same principle. The electrolyte is absorbed in to a glass mat like a sponge, hence the name Absorbed Glass Mat.

When voltage is applied to a battery a chemical reaction is created with the electrolyte. Breaking the electrolyte down in to hydrogen and sulfate. The hydrogen is absorbed into the positive lead dioxide of the battery and the sulfate is absorbed in to the lead. Creating a electron imbalance between the two plates or a charge. The charge is looking for a way back to the negative plate via the boats DC system. It is important to remember it takes time for the electrons to be absorbed deep in to the battery plates. And it takes a lot of volt energy to create the reaction to over come what we commonly is refer to as the resistance to charging.

The best way to check a battery is by checking the specific gravity of the electrolyte. (I’ll get to sealed or AGM batteries in a moment.) When a battery is discharged water is produced lowering the specific gravity to around 1.75 at 0 volts. When fully charged a good gravity is around 2.12 depending on the temperature.

At a full charge each cell should be capable of delivering around 2.2 volts. A battery is considered fully charged at about 12.7 volts when new. As a battery gets older specific gravity goes down and so does the full charge voltage.

The approximate battery voltages for various states of charge.

State of Charge (approx.) and specific gravity.

100% 12.70 2.12

90% 12.50 2.08

80% 12.42 2.07

70% 12.32 2.05

60% 12.20 2.03

50% 12.06 2.01

40% 11.90 1.98

30% 11.75 1.96

20% 11.58 1.93

10% 11.31 1.89

0% 10.50 1.75

How battery charging is supposed to work:

Any battery has an given amount of acceptance or charging amperage at a given voltage and temperature. An example is the acceptance of a typical group 27 automotive battery with a capacity of around 100 amps. The battery will have a maximum acceptance of about 20 amps per hour at 14.2 volts. The 14.2 volts is typical voltage of an automotive alternator and it is considered not to much voltage to ruin a battery and enough voltage to get the job done. Remember voltage is pressure and we are going to stuff amps in to the battery. So if you look at a battery with a state of charge voltage of around 11.5 volts or 25% of its capacity. There is 2.7 volt differential of voltage between the charger and the battery. (When it comes to charging tenths of a volt count!) As the battery becomes charged it starts to close in on our 14.2 volts of charging potential. Decreasing the charging potential to just 1.2 volts at 12.7 volts when fully charged. Another factor is there are simply fewer electrons left in the electrolyte to beak in to hydrogen and sulfate. The battery acceptance will become less so our charge amperage will start to slow to a trickle of around 5 amps. You can see to get that last 10% or so of a battery’s total amp capacity it can take a really long time. When I’m out on my boat I don’t worry about that last little bit of charge. I know when I get back to the dock and plug the boat in to shore power the batteries will get a good topping off.

Battery Chargers:

Modern battery chargers use multi stage charging and temp senders to help with battery charging. On a cold day I might see charging voltages of over 15 volts on a flooded battery. AGM batteries will be at little lower voltage with a max voltage of around 14.6 volts. A typical battery Charger will have a target voltage and will reduce the output voltage from “Bulk” to “Acceptance” and down to “Float” usually set at around 13.5 volts. Most boats sit at the dock with the charger set at a float charge for long periods of time.

Once a boat is no longer plugged in to the dock you would expect to see the float voltage drop to around 12.7 volts after some use. Batteries can carry a surface charge for quite a while. So you might not see a drop in voltage until you apply some load.

Getting a true volt reading is really important for battery monitoring. Gages can be a long way from the battery or part of another electronic system. Meters can show a lot of voltage drop. Giving an inaccurate reading of the battery status. Often lower than at the battery where the reading really needs to be taken. You should check battery voltage at the battery with a good volt meter and compare it against the volt meter at the panel. It is important to note. True battery voltage can only be checked when the battery is at a state of rest. As a battery is being discharged it takes time for the chemical reaction inside the battery to catch up with the loads being applied to the battery. This is an other point of frustration for a lot of boaters. If you are looking at the battery voltage when a heavy load is being applied like when the refrigerator comes on. You will see a low battery volt reading. The best way to get a really get good voltage state of charge is to turn OFF the battery switches and let the batteries settle for a couple of hours. Then go directly to the battery and check the voltage at the battery. That is your state of charge!

Rule of thumb for selecting the right amperage charger for your battery bank. The out put of the charger should be at least 25% of the total amp hour capacity for the battery or battery bank.

Charging multiple battery banks:

A typical yacht will have house battery banks, engine start banks, generator, bow thruster and or stern thruster batteries. It becomes a really complicated to keep it all working. We have to look at all the various chargers, alternator charging, inverter charging, diodes or automatic charge relays and understanding how the battery crossover switches work can be a mind blowing exercise.

When every thing is working right you should get long battery life. But that is not always the case and can have some really damaging consequences. So lets dive in.

Battery Switches:

ABYC requires a battery disconnect switch for each battery and there are many types of switches. They can be in the form of the ON/OFF switch or ONE/TWO/BOTH. The main point of the battery switch is to isolate the battery and be able to cut off power in case of an emergency. There are a few things that can be hooked to the battery direct. Bilge pumps and battery chargers can be connected directly to the battery provided they are fused correctly. Other wise there should not be any thing attached to the battery that does not go to a battery disconnect switch first. A battery can have multiple ON/OFF disconnect switches. Bow thrusters /Anchor windlasses / Inverter-chargers.

Crossover switches or parallel switches that combine two sets of batteries into one battery bank. Crossover switches are most often used to combine the engine start battery and house bank. The thought being if you need the extra energy to get your engine started you can combine the two banks to get the job done. The default setting should be in the OFF position for most cross over switches. You could find you are using your engine start battery as part of your house bank. The same holds true for the BOTH position on a ONE/TWO/BOTH switch.

Labeling your battery switches is really important. Battery ONE or Battery TWO means nothing if you don’t know what the battery is used for. ( A good label maker is a must have on any boat.) One way to check if your engine start batteries are isolated from your house battery is to check the voltage. After the boat is off shore power for a while and a load is applied to the house bank. The house bank should start to loose voltage and the engine start battery should maintain a full charge. It is important to keep isolation between the battery banks. It is the back up system that allows you to deep draw your house batteries with out fear of not being able to start engine or generator in the AM.

Voltage Sensitive Relays:

VSR’s have been in use for years and can work really well for multiple battery charging. A VSR is a switch made to combine two or more battery banks. When voltage goes over a set charging voltage of around 13.5 volts the switch closes. The relay opens again isolating the battery again when the voltage the drops or the changing source is turned off and is usually set at around 12.7 volts. Isolating the two batteries. Common applications are from the engine start battery to the house bank. For when the engine alternator is running. The inverter charger to the engine start bank and can be used to combine thruster batteries to keep them charged.

VSR’s are commonly used in the place of diodes that produce a slight voltage drop and reduce charging voltage. Many boats come from the factory with charging diodes. I have found these systems tend do work well and found little need to replace them with VSR’s.

Inverter Chargers:

Are very common on most yachts today and are capable of operating a number of AC appliances. What is more important about an inverter charger is the charging capabilety. They work exceedingly well when used with the generator. (I cant stress the importance using your generator enough. It absolutely drives me batty to see generators that have almost NO hours on meter.) If you are planning on in stalling an inverter get a good marine intend inverter charger. And have it installed by a good ABYC marine tech. When done right they are the best way to charge, maintain and monitor your house battery bank.

Battery myths and care:

The batteries used in boats are made to cycle hence the term deep cycle. Cycling your batteries is good for them it cleans the plates of sulfate build up. When you go out for a couple of weeks instead topping off your battery banks at 12.7 volts run slightly lower voltage. If you see your batteries drop to 11.5 volts you have used 75% of the battery cycle, it’s not the end of the world. They will charge at higher amperage and bounce back quickly. Remember they were made for this use and couple of weeks of deep draw down will not harm them.

What is hard on batteries is letting flooded batteries get low on water. If you see the top of the plates fill them with water to the eye just below the top. Over filling the batteries is not good for the batteries. Over filling will make a mess on the battery tops and become source of corrosion at the battery terminals. Once charged you can check the batteries with a hydrometer and see how they faired.

A dead cell can occur when a battery is chronically under charged lead sulfate crystals can build up on the plates. The lead sulfate reduces the battery’s capacity and can come in contact with the adjacent plate creating a short and effectively killing the battery. Corrosion can fill bottom of the cell with sediment. The battery is made to contain an amount of sediment at the bottom of the cell. A dead cell is created when material or sediment comes in to contact with the bottom of the plates. Making a dead short in one or more of the cells of the battery. When a battery has a dead cell it will be quite obvious. The hydrometer bulb will not float. The battery will not hold a charge and will go dead when left on its own over a day or so. Batteries that have a dead cell in will often be warm to the touch. The cases may be warped or swollen. Dead cells look like a load to a battery charger and will kick the charger on. Raising the charge rate voltage to “Bulk” and start to over charge the rest of the battery bank. In extreme conditions the boiled sulfuric acid will leave a rotten egg smell in the boat and turn everything made of copper to black.

Dirty and loose battery connections is a real battery killer. Corroded connections and can create resistance. The battery may not get fully charged. Creating sulfated plates or not start the engine at the worst time. So check your cables!

Trickle Battery Chargers:

Once a battery has a full charge you can not charge it any more. A trickle charger acts like a pot sitting on low heat slowly boiling the battery away. Some trickle chargers are aromatic and will turn off the charger when sensing that the battery is at full charge. If you plan on leaving the boat with out shore power. It is better to just turn the battery switch to the “OFF” position. If the battery is in good condition it will be capable of holding a charge for many months.

AGM Batteries:

AGM batteries have a big advantage over flooded batteries. Once installed they need very little maintenance and will stay clean. They can last a really long time, I have often seen them go over ten years of life. AGM batteries have another advantage the resistance to charging is lower than flooded batteries. So AGM batteries have a higher acceptance and therefore charge faster than flooded batteries.

AGM batteries do need to be brought up to full charge and prolonged under charging is hard on them. So over a long period of undercharging the batteries will create a build up sulfate on the surface of plates and they will not take a charge. A good deep cycling is good for batteries and a couple of weeks at a lower voltage will not harm them a bit. They will get a good topping off when you get back to the dock. If you are out for a long period of time a regular good topping off of the batteries is really important.

AGM batteries do need to be brought up to full charge and prolonged under charging is hard on them. So over a long period of undercharging the batteries will create a build up sulfate on the surface of plates and they will not take a charge. A good deep cycling is good for batteries and a couple of weeks at a lower voltage will not harm them a bit. They will get a good topping off when you get back to the dock. If you are out for a long period of time a regular good topping off of the batteries is really important.

AGM batteries are valve regulated and sealed. So the charging voltages are a little lower than a flooded battery. Most battery chargers sold to day have an AGM setting and if you are changing out your flooded batteries for AGM’s you will need to change the charge settings. If you over charge AGM batteries you run the risk of popping the valve and wrecking the battery. Since there is no way to add water to the battery it will over heat and dry out. AGM batteries need to be in a box just like flooded batteries. I have seen over charged AGM batteries literally welded together and the cases split with what looks like jelly coming out of them!

Lithium ion:

I get a lot of calls for Lithium ion systems. The cost of installing lithium batteries is still more than what most boat owners can afford. The advantage of reducing weight, fast charging and many cycles makes them a great choice if you can afford the cost of the change over. I do not recommend just going to the internet and picking up a cheap set of lithium batteries and sticking them in your boat. It is a little more complicated than that. Lithium systems require a more holistic approach. Victron energy is one manufacture leading the way in devolving complete Lithium Ion systems.

AGM batteries do need to be brought up to full charge and prolonged under charging is hard on them. So over a long period of undercharging the batteries will create a build up sulfate on the surface of plates and they will not take a charge. A good deep cycling is good for batteries and a couple of weeks at a lower voltage will not harm them a bit. They will get a good topping off when you get back to the dock. If you are out for a long period of time a regular good topping off of the batteries is really important.

AGM batteries do need to be brought up to full charge and prolonged under charging is hard on them. So over a long period of undercharging the batteries will create a build up sulfate on the surface of plates and they will not take a charge. A good deep cycling is good for batteries and a couple of weeks at a lower voltage will not harm them a bit. They will get a good topping off when you get back to the dock. If you are out for a long period of time a regular good topping off of the batteries is really important.